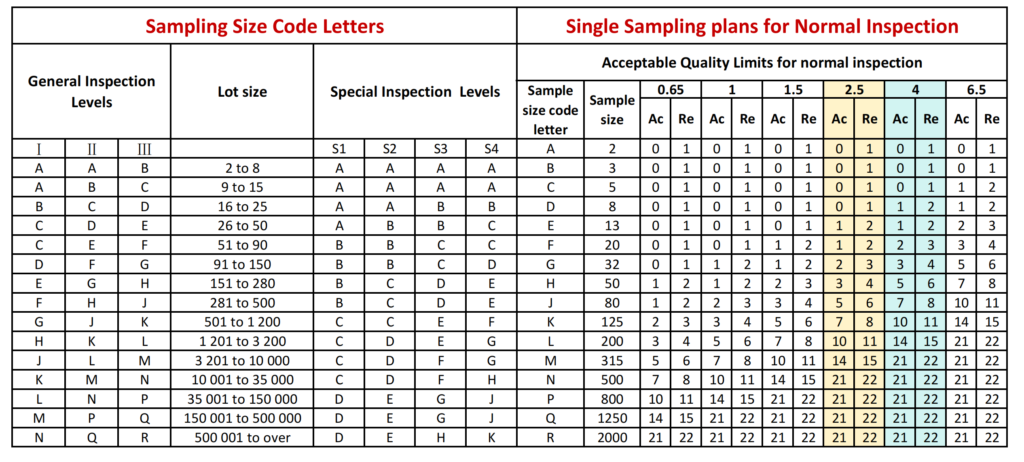

In custom tin box field, e.g candy tins, chocolate tins, candle tins ect, we normally adopt General inspection level II AQL 0/2.5/4.0 to do product inspection before shipping.

Do you know what quality issues you may face and are they accepted or rejected? As working in tin box field over 7 years, let me show you through this article.

AQL 0/2.5/4.0 means 3 different kinds of issues, they are: Critical defect, Major defect and Minor Defect.

Critical defects.

What are Critical defects? Material, color, shape, and dimension are different from approved samples. For example, customers wants Pantone 485C, but you printed it 186C, if this happens, the whole mass production is unacceptable. Dimension, the general standard is ± 1mm, some factories can reach ± 0.5mm. If it’s more than 1mm, reject too. I faced this issue before, we made the candle tin 1.3mm higher than the approved sample, which caused it’s not able to fit in the color paper box outside.

Major defects. Below issues belong to major defects.

- Sharp metal edge: This problem may happen at areas like: Sealing bottom, corner of inner/outer rolling edge, rolling edge of round tin. When the punching machine works on these areas, if mold is not smooth enough, it causes such problems. So we have to pay attention to the “maybe exist” problem from the mold developing stage.

- Un-removable dirt: Normally appears at the printing stage. Offset printing, maybe some dust falls on the rubber roller or rubber roller not clean enough, after drying through the high-temperature oven, the dirty is un-removable.

- Scratches and dent visible when viewing product from 50cm away. This problem may happen at all stages of production. From material preparation, printing, and shearing, to punching, sorting and inspection, as it’s metal, easily to be scratched, so must be careful.

- Rust or oxidation occurs on product. This mainly because of two reasons: 1) the coating at the surface of tin box was destroyed during punching. Maybe molds are not smooth or not adjusted to good condition. 2) The coating is too thin.

Minor defect

- Removable dirt. Maybe engine oil.

- Scratch and dent invisible when viewing product from 50cm away.

Here put the AQL form for your reference.

If you want to know more about the quality issues of tin box or may want to import tin box to pack your product someday, pls email me or whatsApp me freely. I’m sure my rich experience could benefit you. Email: lily.chiang1995@gmail.com, WhatsApp/Wechat: +86 150 1365 0507