We need 4 stamping steps to make a tin lid with inner curling, assuming we have printing tin sheets ready. Blanking -> Trimming -> Pre-curl -> Curling, this article will show you these 4 steps with video & photos.

Stamping step 1: Blanking

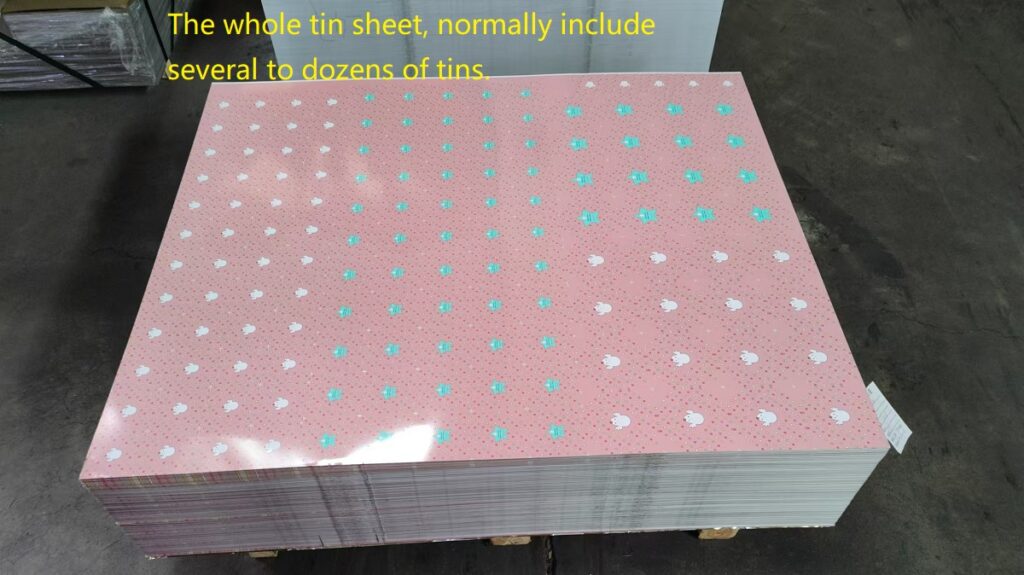

Normally we can print several to dozens of tins on one tin sheet. After printing, we’ll shear the tin sheets and make them suitable for stamping.

After blanking, we can get a rough tin lid from flat tin sheets, but without a curling edge.

Stamping step 2: Trimming

We must cut the extra material to get the curling edge that won’t hurt our hands.

Stamping step 3: Pre-curl

If it’s an outer curling lid, we can go with curling directly. But if it’s inner curling, we have to do pre-curl.

Stamping step 4: Curling

We will finally get ready lids after curling.

See, even a very simple tin lid, we need 4 punching machines to produce it, and each machine installed with corresponding molds. So we know we need 4 molds to make a tin lid. Here is a video showing the production process. Want to know more, pls contact me freely. Email: lily.chiang1995@gmail.com; WhatsApp/Wechat/Cell phone: +86 150 1365 0507